Price: [price_with_discount]

PLEASE NOTE:

1.This is a customized machine. The worth on the web page is just a deposit, and doesn’t embody delivery, equipment and packaging charges.

2.Please contact Amanda for a free quote❤

Whatsapp/WeChat/Phone quantity : +8613937189170

Email : yugongmachine@yg797.com

China Manufacturer Automatic Small Toilet Tissue Paper Roll Rewinding Converting Making Machine

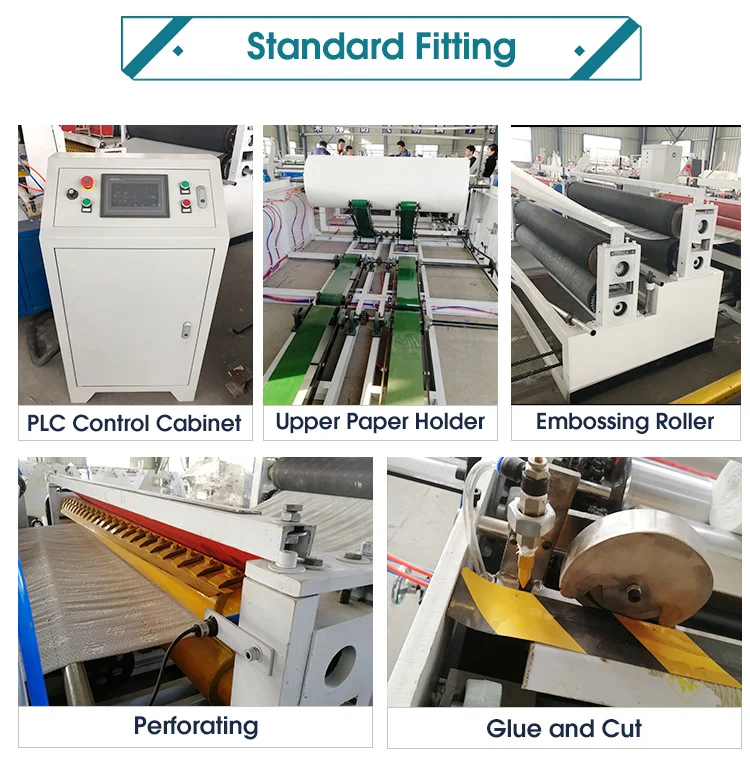

This machine adopts worldwide new PLC laptop programming know-how (system will be upgraded), frequency management, automated digital brake. The touch-type human-machine interface working system makes use of a coreless rewind forming system. utility the PLC program wind column forming know-how achieves the traits of quicker rewinding and extra lovely molding.

|

Machine Model |

1092/1575/1880/2100/2400 |

|

Paper Width(mm) |

1092mm/1575mm/1880mm/2100mm/2400mm |

|

Paper Diameter(mm) |

φ1200mm(Please Specify) |

|

Paper Core Inner Diameter |

φ76mm(Please Specify) |

|

Product Diameter |

φ40mm-200mm |

|

Paper Backing |

1-4layer,normal chain feed or repeatedly variable transmission feed paper |

|

Punch |

2-4 Knife,Spiral Cutter Line |

|

Hole Pitch |

Positioning of Belt and Chain Wheel |

|

Control System |

PLC Control,Variable Frequency Speed Control,Touch Screen Operation |

|

Product Range |

Core Paper,Non Core Roll Paper |

|

Drop Tube |

Manual,Automatic(Optional) |

|

Non core roll paper |

automtic core pulling |

|

Production Speed |

150-280m/min |

|

Spray,Cutting and Rewinding |

Automtic |

|

Finished product launch |

Automtic |

|

Point Moving Mode |

Before and After the Point Moving |

|

Power Configuration |

380V50HZ |

|

Required air strain |

0.5Mps(The Self) |

|

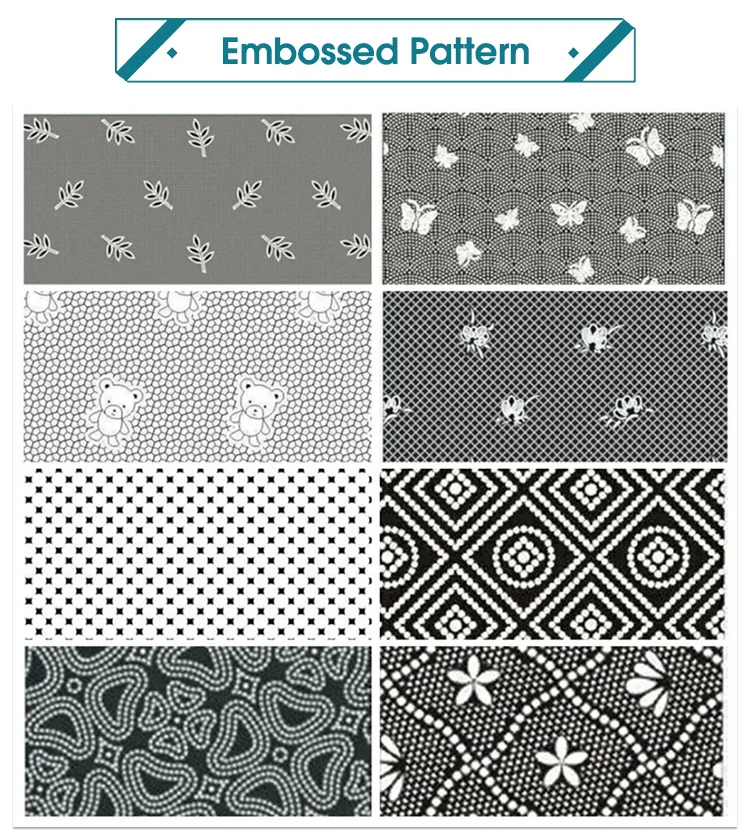

Embossing |

Single Embossing,Double Embossing(Steel Roller to Wool Roller,Steel Roller)Optional |

|

Blank Holder |

Airbag Control,Cylinder Control,Steel to Steel Structure |

|

Outline Dimension |

6200mm-7500mm*2600mm-3200mm*1750mm |

|

Machine Weight |

2900KG-3800KG |

Working Principle

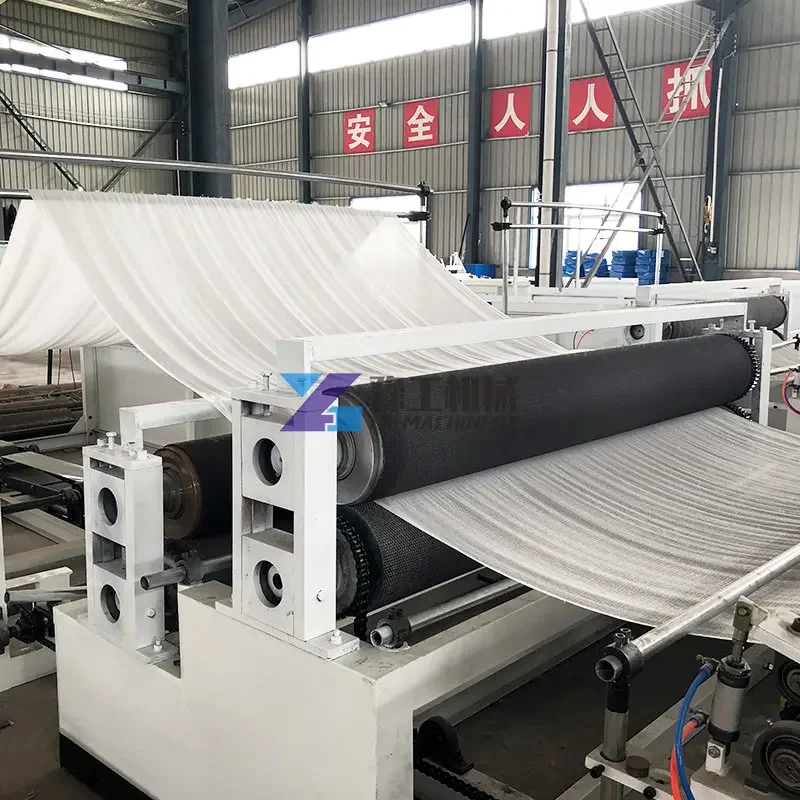

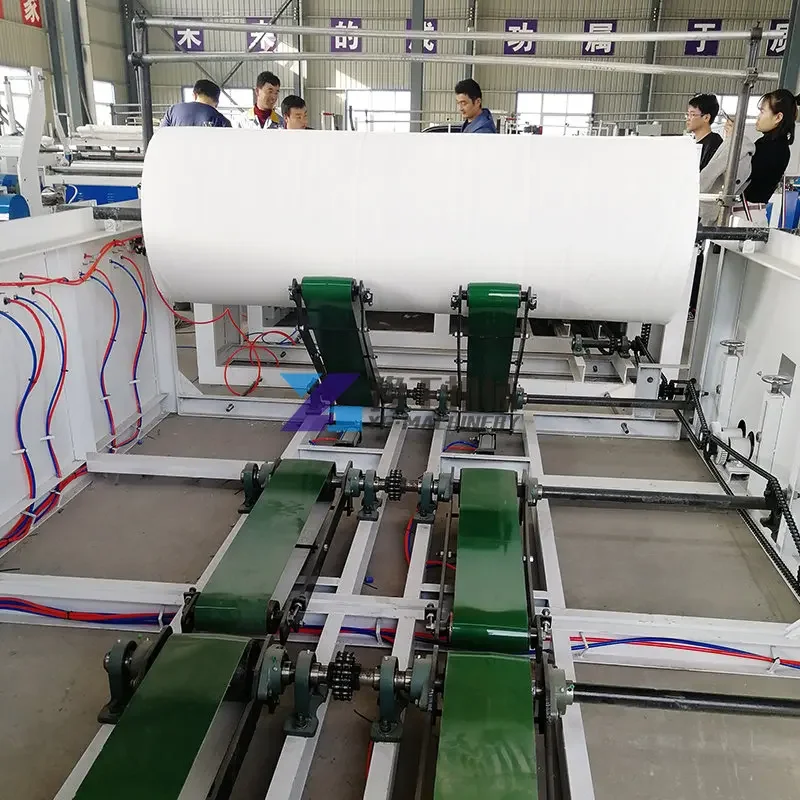

Four-roller automated feeding→synchronous conveying→embossing→punching→automated winding→chopping→packing→sealing.

1. Rewinding—The important objective of the bathroom paper rewinding machine is to course of the big shaft paper into an extended strip of bathroom paper roll.

2. Cut the paper—The lengthy piece of bathroom paper lower by the paper cutter is lower into semi-finished merchandise of the size required by the shopper.

3. Packaging—Packaging will be packaged in a packaging machine or manually wrapped, and the semi-finished merchandise of the bathroom paper are packaged and sealed by a sealing machine.

Performance Characteristics

1. Using PLC laptop to program the completed paper within the rewinding course of to attain the tightness and looseness of the totally different tightness to unravel the looseness of the completed product attributable to long-term storage.

2. Full-automatic rewinding machine can select double-sided embossing, gluing compound, which may make paper extra tender than single-sided embossing, the impact of double-sided completed merchandise is constant, and every layer of paper doesn’t unfold when used, particularly appropriate for processing. Roll up kitchen paper towels and cut back weight by 15% or extra when completed in the identical dimension.

3. The machine is supplied with processing unintentional, stable, paper tube rest room paper, which may immediately swap between merchandise, and will also be chosen in response to consumer wants.

4. Automatic trimming, glue spraying, sealing, and shafting are accomplished synchronously, in order that there is no such thing as a paper loss when the roll paper is lower into the band noticed and packaged, which tremendously improves the manufacturing effectivity and the grade of the completed product. Easy to allow.

5. Pneumatic belt feeding, double reel and every axis of the unique paper have impartial stress adjustment mechanism

Whatsapp/WeChat/Phone quantity : +8613937189170

Email : yugongmachine@yg797.com