Price: [price_with_discount]

# Parameters

❤ Main Product: Hot Air Gun

❤ Plug Type: EU Plug / US Plug /AU Plug(non-obligatory)

❤ Heat Gun Power: 300W

❤ Achievable Temperature: 180- 200℃

❤ Rated Voltage: EU Plug & AU Plug –220V / US Plug –110V

❤ Widely Application: DIY Craft Embossing, Shrink Wrapping PVC, Drying Paint, Clay, Rubber Stamp, and so forth

# About This Item

❤ Mini Heat Gun:

Dimensions 225x45mm / 8.86×1.77in (Approx.) 3.28FT Long Cable (Approx.)

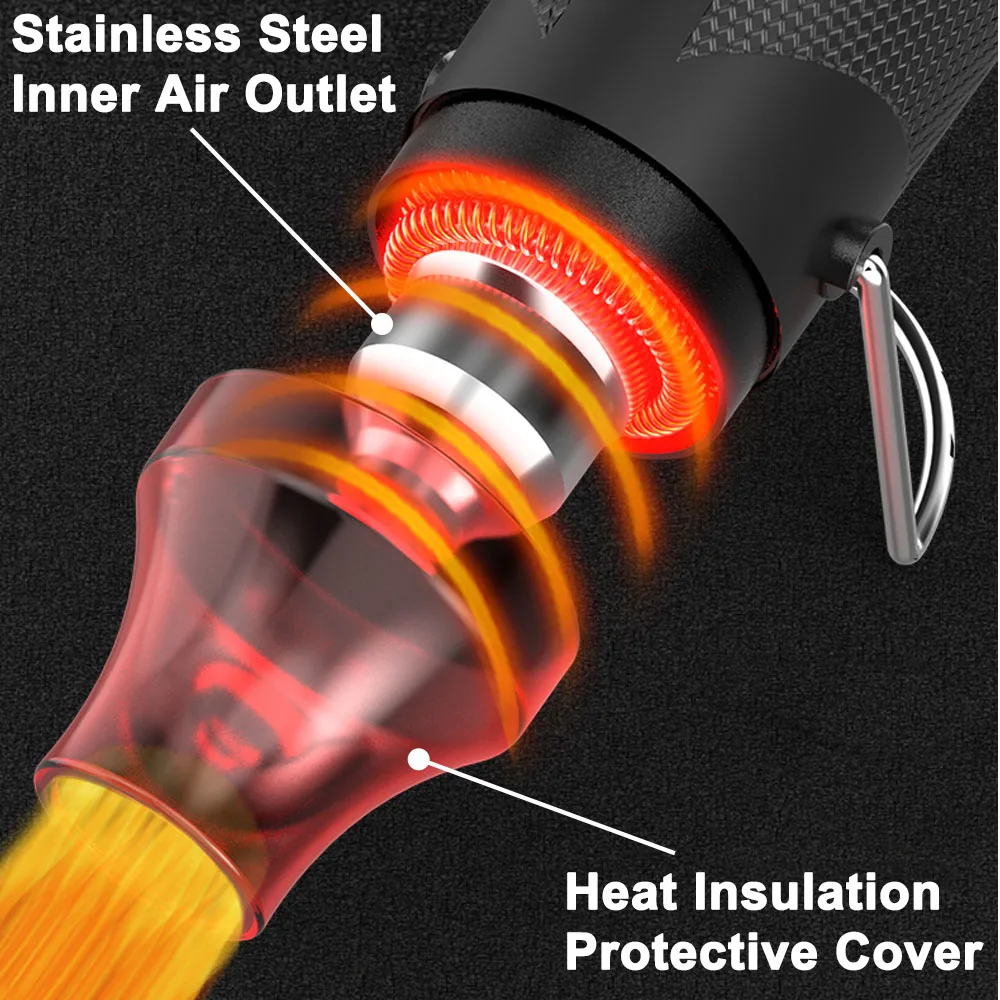

❤ Safety Hot Air Gun:

Mini Craft Heat Gun for Epoxy Resin adopts anti-scalding non-slip handles on the skin, impartial swap buttons, and high-quality chrome steel air retailers and chrome steel brackets inside, making the use course of safer.

❤ Cooling Holes:

The temp of the nozzle might attain 180-200° in seconds. The vent on the rear can cut back the inner excessive temperature and extend the service life.

❤ Easy to Use:

The handing half adopts salient level nonskid designs that trigger secure handholding with small energizing!

# How to Use the Heat Tool

★ Plug within the warmth instrument. Hold the product as proven on the pict. (Do not contact the recent nozzle.)

★ Keeping 3-5cm distance from work and a few 45-degree angle to warmth till it’s accomplished. (Do not blow the recent air gun instantly at 90° to the article.)

★ Warm Tips:

The temp of the nozzle might attain 200° in seconds, please don't use it for greater than 10 minutes at one time .

If the temperature of the fuselage will increase considerably, please shut the warmth gun and wait for cooling earlier than utilizing it.

It cannot be usedin industrial facets akin to disassembly and welding of small iron sheet elements and patch built-in circuits.

❤ Main Product: Hot Air Gun

❤ Plug Type: EU Plug / US Plug /AU Plug(non-obligatory)

❤ Heat Gun Power: 300W

❤ Achievable Temperature: 180- 200℃

❤ Rated Voltage: EU Plug & AU Plug –220V / US Plug –110V

❤ Widely Application: DIY Craft Embossing, Shrink Wrapping PVC, Drying Paint, Clay, Rubber Stamp, and so forth

# About This Item

❤ Mini Heat Gun:

Dimensions 225x45mm / 8.86×1.77in (Approx.) 3.28FT Long Cable (Approx.)

❤ Safety Hot Air Gun:

Mini Craft Heat Gun for Epoxy Resin adopts anti-scalding non-slip handles on the skin, impartial swap buttons, and high-quality chrome steel air retailers and chrome steel brackets inside, making the use course of safer.

❤ Cooling Holes:

The temp of the nozzle might attain 180-200° in seconds. The vent on the rear can cut back the inner excessive temperature and extend the service life.

❤ Easy to Use:

The handing half adopts salient level nonskid designs that trigger secure handholding with small energizing!

# How to Use the Heat Tool

★ Plug within the warmth instrument. Hold the product as proven on the pict. (Do not contact the recent nozzle.)

★ Keeping 3-5cm distance from work and a few 45-degree angle to warmth till it’s accomplished. (Do not blow the recent air gun instantly at 90° to the article.)

★ Warm Tips:

The temp of the nozzle might attain 200° in seconds, please don't use it for greater than 10 minutes at one time .

If the temperature of the fuselage will increase considerably, please shut the warmth gun and wait for cooling earlier than utilizing it.

It cannot be usedin industrial facets akin to disassembly and welding of small iron sheet elements and patch built-in circuits.