Price: [price_with_discount]

M3-M36 220V CNC Universal Type Servo Electric Tapping Machine Electric Tapper Threading Tool Steel Aluminum Power Drilling

Notice: The machine with out work desk.

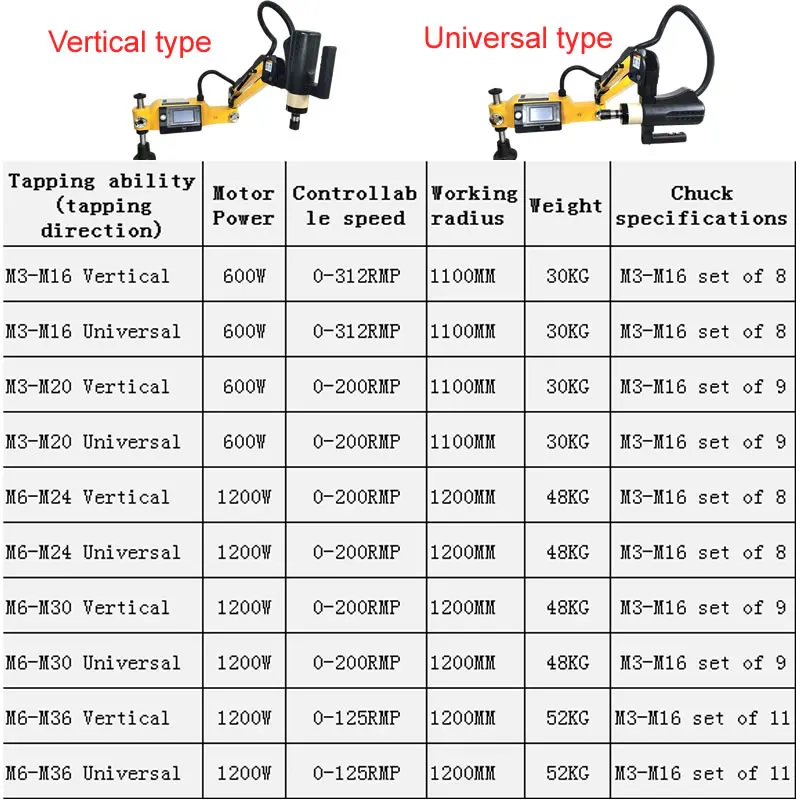

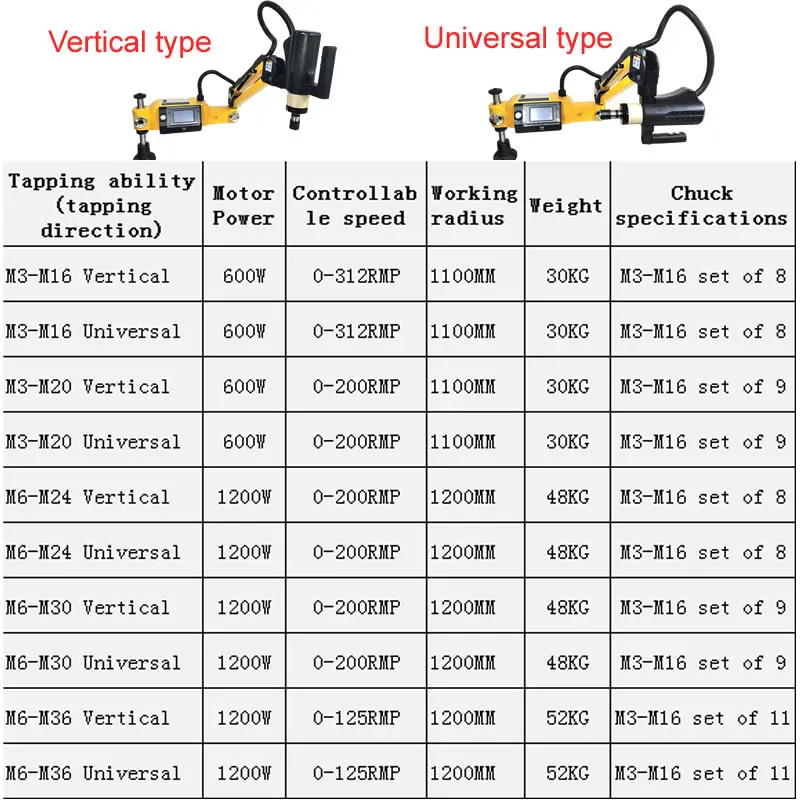

Parameters

|

Tapping skill (tapping course) |

Motor Power |

Controllable pace |

Working radius |

Weight |

Chuck specs |

|

M3-M16 Vertical |

600W |

0-312RMP |

1100MM |

30KG |

M3-M16 set of 8 |

|

M3-M16 Universal |

600W |

0-312RMP |

1100MM |

30KG |

M3-M16 set of 8 |

|

M3-M20 Vertical |

600W |

0-200RMP |

1100MM |

30KG |

M3-M16 set of 9 |

|

M3-M20 Universal |

600W |

0-200RMP |

1100MM |

30KG |

M3-M16 set of 9 |

|

M6-M24 Vertical |

1200W |

0-200RMP |

1200MM |

48KG |

M3-M16 set of 8 |

|

M6-M24 Universal |

1200W |

0-200RMP |

1200MM |

48KG |

M3-M16 set of 8 |

|

M6-M30 Vertical |

1200W |

0-200RMP |

1200MM |

48KG |

M3-M16 set of 9 |

|

M6-M30 Universal |

1200W |

0-200RMP |

1200MM |

48KG |

M3-M16 set of 9 |

|

M6-M36 Vertical |

1200W |

0-125RMP |

1200MM |

52KG |

M3-M16 set of 11 |

|

M6-M36 Universal |

1200W |

0-125RMP |

1200MM |

52KG |

M3-M16 set of 11 |

Voltage: 220V

Motor Power: 600W / 1200W

Electric present: 50HZ/60HZ

Spindle pace: 0-312/RPM

Working radius: 1100mm /1200mm

Working angle: Universal kind / Vertical kind

Control panel: Touch display screen

Tap capability: M3-M36

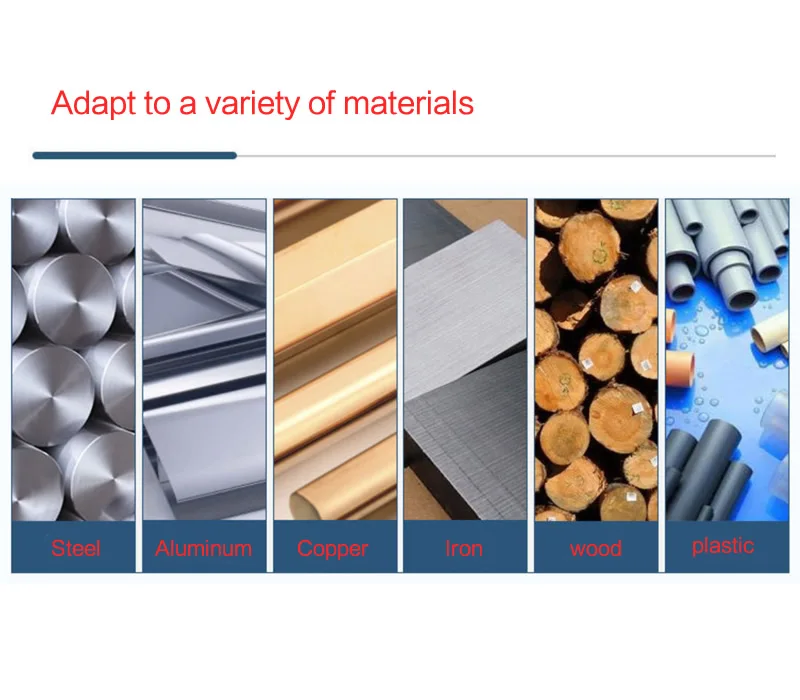

Suitable for: metal, aluminum, copper, iron, wooden, plastic, and many others..

Packing checklist

Tapping machine *1

Torque chuck field *1

Wrench *1

Power cable *1

Introduction

Electric tapping machine is relevant to all equipment manufacturing trade, machine device, mould equipment, plastic equipment, printing equipment, packaging equipment producers, engineering equipment, car motorbike components, aviation engines, rolling inventory, tobacco equipment and common equipment and different industries.

Machine options

1.The tapping motor of the tapping machine is balanced and perpendicular to the suspension assist body, which may maintain the tapping motor shifting to any place and might be stored perpendicular to the workbench.

2.The faucet of the tapping machine is supplied with overload safety system. With the clamping head of overload safety system, the security clutch might be adjusted when the tapping exceeds the rated torque, and may keep away from injury to the faucet.

The machine can be utilized in single-phase 220V energy provide.

3. It has the benefit of excessive value efficiency, cheaper price and extra perform than the home and worldwide mannequin machines, and many innovations surpass different manufacturers.

4. Advanced mechanical design, every kind of processes are utilized in moulding manufacturing, with low value and exquisite look.

5. Simple and versatile operation, in a position to rapidly find and precisely course of sophisticated and hulking work.

6. Can (elective) common head, the work head can modify at any Angle, vertical, horizontal, lateral, excessive and low can faucet the silk.

7. The taper sleeve has an overload safety system to make sure that it doesn’t injury the faucet, the load steadiness within the tapping course of, the excessive precision of the screw processing, and the safety of the torsion power.

8. Infinitely variable pace, can modify any pace, the pace might be set on the controller.

9.handbook, automated and hole three modes of labor are your selection.

10.Automatic mode can management the tapping depth successfully, with out operation button, it’s managed routinely by the depth controller.

11. Rapid positioning, fast tapping pace and excessive manufacturing effectivity.

12.Servo drive management, overcome the constraints of pneumatic tapping machine, lathe, drilling machine or handbook tapping machine.