Price: [price_with_discount]

Electrical Automatic Bobbin Winder with Thread Stand for Domestic Industrial Sewing Machine Thread Winder Winding Assistant Tool

Feature:

1. Portable: The compact wire winder means that you can simply carry it with you, a easy one contact wire winder.

2. Features: Bottom suction cup design, extra steady when winding. Comes with lock, hidden deal with and dustproof.

3. Two Kinds Of Bobbin Fixing Structures: The Bobbin Of Industrial Household Sewing Machine Can Be Wound.

4. Two Power Supply Modes: USB charging(USB Type-C charging cable not included) or dry battery energy provide(Battery not included), inbuilt cupboard space.

5. High Speed Motor: Use this machine to wind the bobbin shortly and evenly, and mechanically cease when the bobbin is full.

2. Features: Bottom suction cup design, extra steady when winding. Comes with lock, hidden deal with and dustproof.

3. Two Kinds Of Bobbin Fixing Structures: The Bobbin Of Industrial Household Sewing Machine Can Be Wound.

4. Two Power Supply Modes: USB charging(USB Type-C charging cable not included) or dry battery energy provide(Battery not included), inbuilt cupboard space.

5. High Speed Motor: Use this machine to wind the bobbin shortly and evenly, and mechanically cease when the bobbin is full.

Specification:

Item Type: Bobbin Winder

Product Material: Plastic, Stainless Steel

Product Specification: 1 Piece

Product Use: Household

Applicable Scenarios: Most Scenarios

Battery: 2 x AA Batteries (Battery Not Included)

Product Size: Approx 8.8 x 14 x 10cm / 3.4 x 5.4 x 3.9in

Package List:

1 x Electric Winding Machine

1 x English User Manual

Note:

Please be aware that the brand new kind and outdated kind of this product can be despatched randomly, and ensure you is not going to thoughts earlier than ordering.

How to make use of:

1. Remove the battery cowl from the backside of the machine.

2. Insert 2 x 1.5VAA batteries (not included) as proven in the image, then reattach the battery cowl. Or plug the USB information cable into the Type C socket and provide energy via the DC5V energy adapter. Note: Use solely non rechargeable batteries.

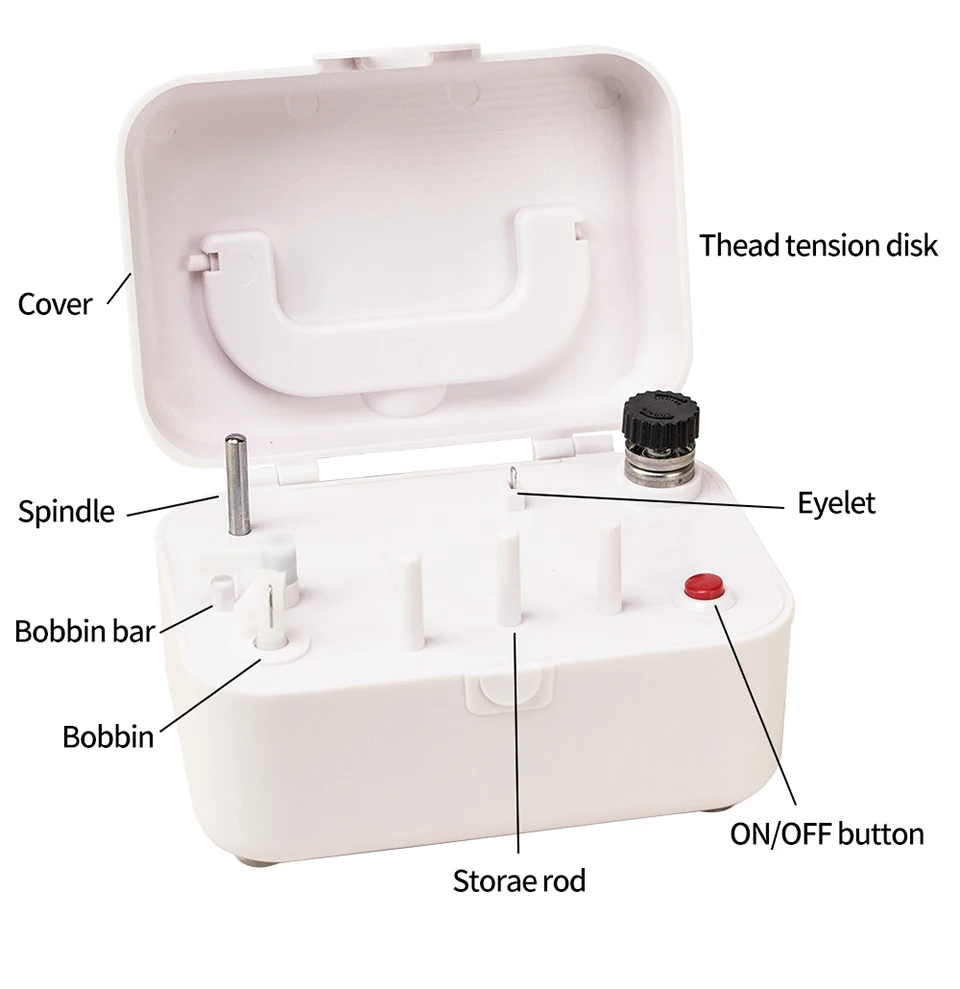

3. Pull up on the locking tab to open the high cowl.

4. Raise the spindle to the totally prolonged place and place the spool on the spindle.

5. Following the numbers and route arrows, cross the thread between the eyelet and the two clips of the suture rigidity disc. Pass the finish of the thread via the gap in the bobbin, insert the bobbin into the winding shaft, and flip the bobbin barely till the spring on the shaft snaps into place.

6. Make certain the bobbin bar is put in between the high and backside rims of the bobbin.

7. Press the "ON" button to begin. Winding stops mechanically when the bobbin is full. If you need to modify the winding quantity of the bobbin by you